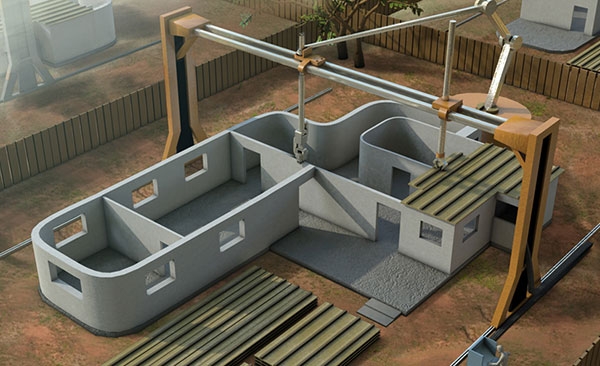

A new architectural revolution just might be brewing at the University of Southern California, and this latest mutiny looks like the start of an engrossing Hollywood sci-fi movie. But in this case, there is plenty of science, very little fiction and the possibility of large residences and buildings in the future being crafted by giant 3D printers! Professor Behrokh Khoshnevis is the man behind the fascinating and ground-breaking technology of Contour Crafting. And it is this innovative marvel that is currently allowing scientists to test out a giant 3D concrete printer that could potentially build a 2,500-square-foot home in less than 24 hours.

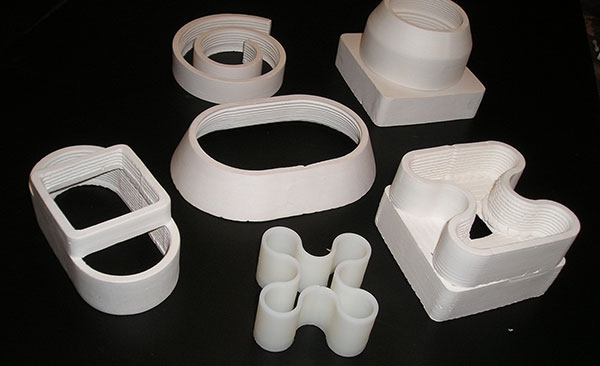

While this might sound like a distant and unrealistic dream to many out there, the fact is that this new technology is not all that different from the normal 3D printers that are currently available. The large 3D printer developed by Professor Khoshnevis and his team scales up things significantly. While the technical know-how behind the creation of these giant 3D printers is not that straightforward, the basic idea remains the same. Contour Crafting promises to slash both the cost and the time of future constructions significantly by crafting sturdy and versatile structures in an uber-quick fashion.

Contour crafting involves two rails being laid out on a leveled construction site, which will facilitate the movement of the computer-controlled arm. While a components-placing arm will shape the outlines of the structure, the nozzle will fill them with concrete to create entire houses in a matter of mere hours.

A Future Filled With Possibilities

If and when Contour Crafting graduates from the lab and enters the real world, the technology can be used to create instant emergency homes in disaster-hit areas. Walls crafted by this new 3D printer have proven to be far sturdier than those of current homes built using the latest construction techniques. Providing instant, affordable homes, Contour Crafting could solve serious housing problems faced in developing and under-developed countries across the globe.

Of course, with every new machine, there is a perceived threat among millions that they would be out of a job. In case of Contour Crafting, the notion is most likely misplaced. Since these 3D concrete printers only craft the outer shell, human services are still an absolute must. While a few might still feel the pinch, Khoshnevis is confident most will find a way to work along with the new system.

While it might take many more years before we actually see a prototype crafted for industrial use, it is undeniable that these are the first steps toward an entirely new era in architecture and design. And Professor Khoshnevis insists that the future is far more exciting than the present, as Contour Crafted buildings only depend on the blueprint that you feed into the machine. Simply change the program to alter the design of the house… The possibilities are endless!